Acid Zinc Plating Solution

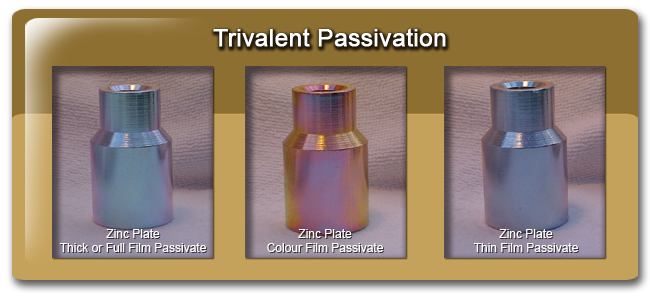

Zinc plating is used to provide corrosion protection and can be deposited in varying thicknesses from 5 to 25 μm depending upon the application of the component and the operating environment , zinc plating is invariably passivated in a chromate solution to enhance the corrosion resistance of the zinc deposit, further treatments can be applied after Passivation such as; Sealants to further improve corrosion resistance and lubricants with a wide range of friction coefficients to improve the torque characteristics of fasteners and joint requirements.

The Acid Zinc Plating solution which A1 Plating use combines excellent throwing power with a high plating rate and has a high cathode efficiency, which makes this zinc plating solution ideal for plating cast iron and high carbon steels. The plating solution reduces the possibility of hydrogen embrittlement of hardened steel components with a bright durable finish.

We at A1 Plating have been using this plating solution since the early seventies and found it to be a good all round performer with excellent results every time.

A1 Plating Customers

Automotive, Aerospace, Commercial Vehicles, Conveyor Systems, Engineering, Earth Moving, Forestry, Gas Industry, Hydraulic Fittings, Lifting Gear, Oil Industry, Mobility, Rail Industry, Shipping, Shop Fitting, Telecommunications.